Towards Multi-Sensor Approach

Generally, conditioning monitoring of a machine is done by looking at a sensor measurement (Eg. Temperature, Vibration ) and imposing bounds to it, i.e. under normal operating conditions, the measurement values are bounded by a maximum and minimum value (similar to control charts). Any deviation in the defined bounds sends an alarm. This is often generally defined as anamoly detection.

However, this method often sends false alarms (false positives) or misses an alarm (false negative). Furthermore, a single signal is observed/analysed in isolation. For example, an alarm may sound if the temperature exceeeds a certain level. A system defined above often cannot look at mutiple parameters and come to a conclusion about the state of a machine. Or technical parlance, one cannot take advantage of the multi-dimensionality of the data.

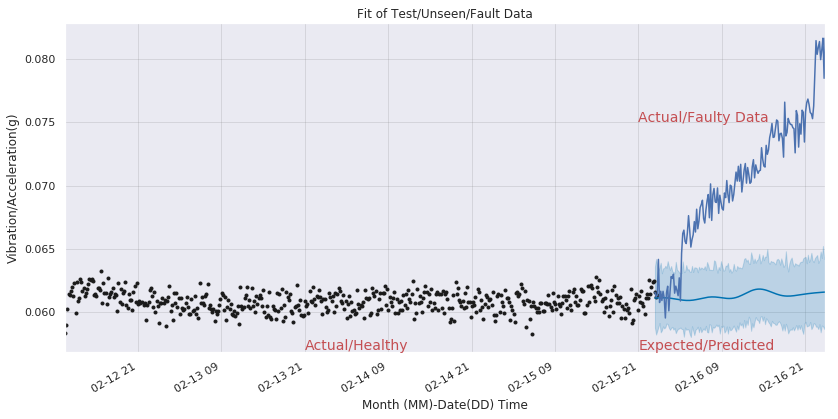

Anamoly detection using a one variable (vibration in a bearing dataset) is explored in detailed in my blog article. By analysing past trends of healthy (black points in graph), the model learns the expected trend with acceptable variance .A trained model predicts the trends for the future (The blue line represents the expected values from 2004-02-15, 23:42:39 with the light blue portion showing the acceptable variance) and if any deviation is observed, an alarm can be raised.

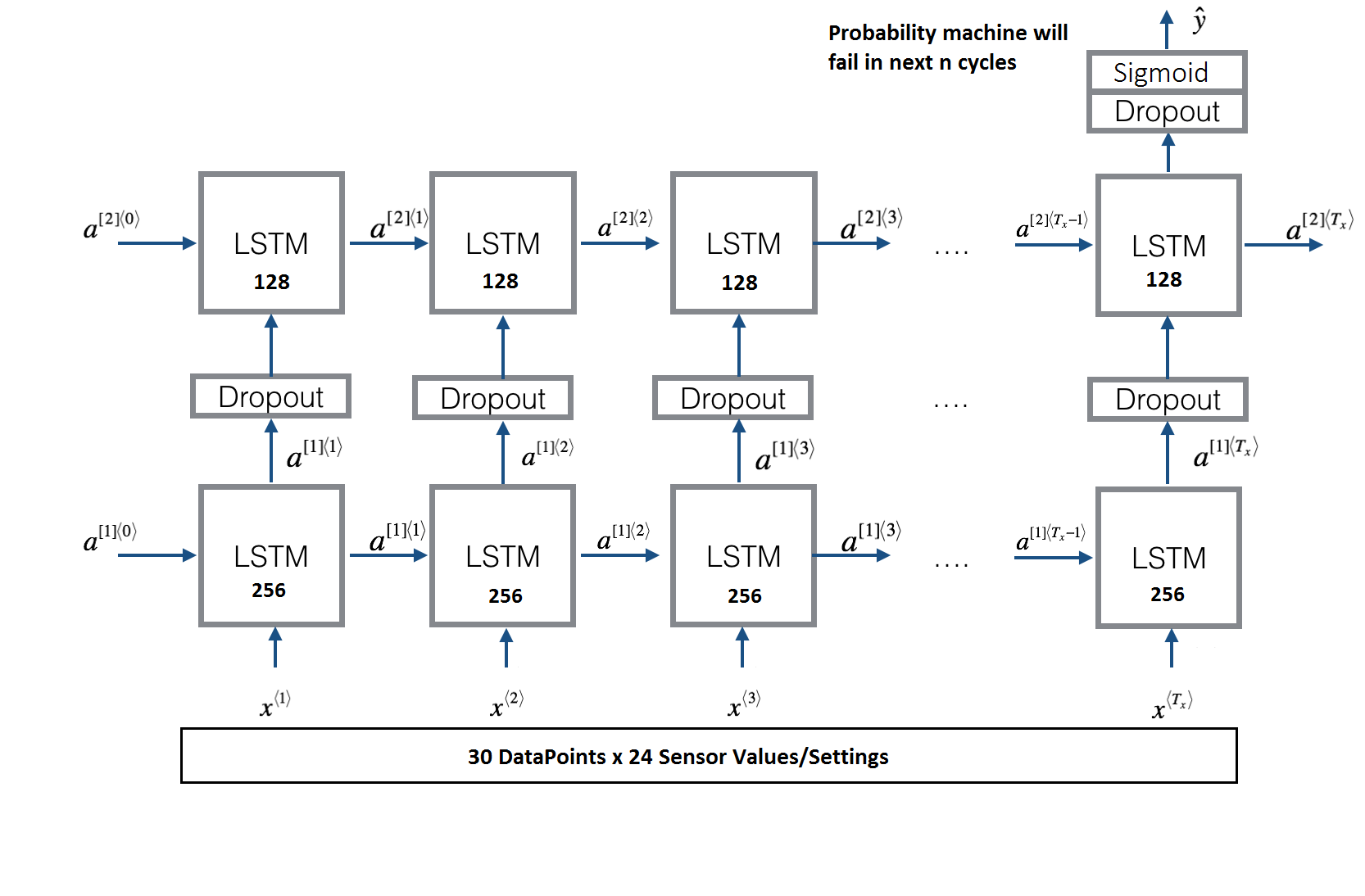

The same principle hold true for analysing multiple signal (multi-dimensional) at a time and creating a single metric like, the health score/ residual useful life of a machine. The following sections demos one such illustartion of analysing multiple signals (multi-dimensional) to guage " What is the probaility the equipment will fail in next n cycles?"